This guide provides comprehensive information on purlin spans, encompassing factors influencing purlin spacing, common run systems, bridging importance, span tables, calculations, material considerations, building code compliance, and concluding remarks.

Introduction

Purlins are essential structural components in roof systems, serving as horizontal beams that support the roof deck and distribute loads effectively. The purlin span, or the distance between two consecutive purlins, is a crucial factor determining the strength and stability of the roof structure. Understanding the principles of purlin span calculation and design is paramount for ensuring a safe and durable roof.

This guide delves into the intricacies of purlin span, exploring the various factors that influence the optimal spacing of these critical components. We will cover essential concepts like load bearing, material properties, and building code requirements. By examining these aspects, we aim to provide a comprehensive understanding of how to determine the appropriate purlin span for a particular roof design.

Whether you are a homeowner planning a roof renovation, a contractor working on a new construction project, or an engineer designing a complex building, this guide serves as a valuable resource for navigating the complexities of purlin span considerations. It will empower you to make informed decisions that ensure the structural integrity and longevity of your roof.

Factors Affecting Purlin Span

Several factors come into play when determining the appropriate purlin span for a roof structure. Understanding these factors is crucial for ensuring structural integrity and safety. Here’s a breakdown of the key considerations⁚

- Roof Load⁚ The weight the roof needs to support, including the weight of the roofing material, insulation, snow load, and potential live loads (people or equipment), is a primary factor. Heavier loads require closer purlin spacing.

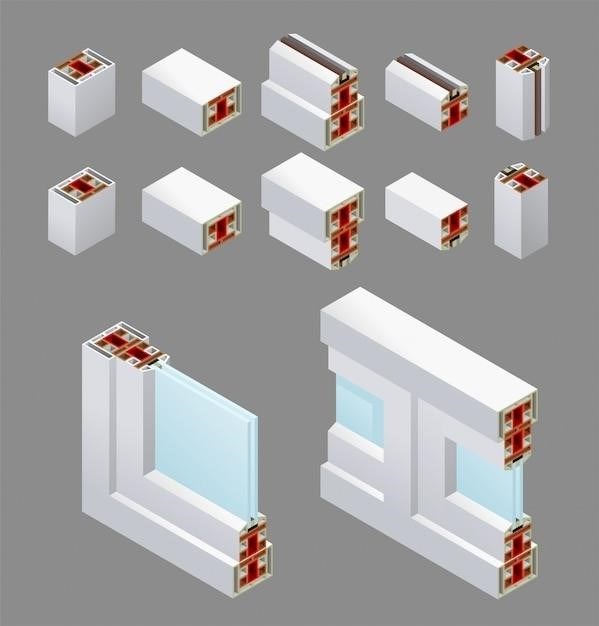

- Purlin Material⁚ The material used for the purlins, whether steel, wood, or another material, impacts its strength and stiffness. Steel purlins typically offer greater strength and can span longer distances than wood purlins.

- Purlin Section⁚ The size and shape of the purlin section, including its depth and cross-sectional area, influence its load-carrying capacity. Larger and deeper sections can support heavier loads and longer spans.

- Roof Slope⁚ The slope of the roof affects the distribution of loads. Steeper slopes distribute loads more evenly, allowing for greater purlin spans.

- Run System⁚ The method of installing the purlins, such as single-span or multi-span systems, impacts the overall span. A single-span system involves a single purlin spanning the entire length of the roof, while a multi-span system utilizes multiple purlins with overlapping spans.

- Building Code Requirements⁚ Local building codes specify minimum purlin span requirements based on factors like roof load, material, and wind pressure. Adherence to these codes ensures structural safety and compliance.

By carefully evaluating these factors and applying appropriate engineering calculations, you can determine the optimal purlin span for your specific roof design.

Common Run Systems

The manner in which purlins are installed significantly influences their effective span and overall roof structure performance. Run systems refer to these installation methods, each offering distinct advantages and limitations. Here’s a look at some common run systems used in roof construction⁚

- Single Span System⁚ This system involves a single purlin spanning the entire length of the roof. It’s a straightforward approach but typically limits the span due to the need to support the entire roof weight. It’s often used for shorter spans, like smaller residential structures.

- Multi-Span System⁚ In this system, multiple purlins are used, with each purlin spanning a portion of the roof. The purlins are typically overlapped at their ends, creating a continuous support system. Multi-span systems allow for greater spans and distribute loads more effectively, making them suitable for larger buildings.

- Lapped System⁚ This system involves overlapping purlins to increase their effective span. The purlins are lapped at their ends, creating a continuous support system. Lapping provides additional strength and allows for longer spans.

- Continuous System⁚ In this system, purlins are installed continuously along the length of the roof, without any breaks or interruptions. This system provides the greatest strength and stability, allowing for the longest spans. It’s commonly used for large industrial buildings and structures with significant roof loads.

The choice of run system depends on factors like roof size, load, and desired span. Careful consideration of the run system is crucial for ensuring the structural integrity and longevity of your roof structure.

Importance of Bridging

Bridging, often referred to as “purlins bridging,” plays a crucial role in enhancing the stability and load-bearing capacity of purlin systems. These are typically short pieces of wood or metal that are installed perpendicular to the purlins, creating a series of interconnected supports across the span. While they may seem like a minor detail, their impact on roof structure is significant. Here’s why bridging is essential⁚

- Preventing Sagging⁚ Purlins, especially those spanning long distances, are susceptible to sagging under the weight of the roof and its contents. Bridging acts as a lateral support, preventing the purlins from bowing or deflecting under load. This ensures a consistently flat and stable roof surface.

- Distributing Loads⁚ Bridging effectively distributes loads across the entire purlin system. Instead of a concentrated load on a single purlin, the load is spread out to multiple purlins through the interconnected bridging. This significantly reduces stress on individual purlins, enhancing the overall structural integrity of the roof.

- Enhancing Stiffness⁚ Bridging increases the overall stiffness of the purlin system, making it more resistant to vibrations, wind loads, and other external forces. This is especially important for roofs exposed to harsh weather conditions or frequent seismic activity.

- Preventing Purlin Rotation⁚ Excessive rotation of purlins during construction or due to load shifts can cause misaligned fastenings and stress on the roof sheeting and fasteners. Bridging helps stabilize the purlins, minimizing rotation and ensuring proper alignment.

The use of bridging is generally recommended for purlin spans exceeding a certain limit, as determined by building codes and engineering specifications. The frequency and type of bridging will vary based on the purlin material, span length, and anticipated loads.

Purlin Span Tables

Purlin span tables are invaluable resources for engineers, builders, and contractors involved in roof construction. These tables provide pre-calculated data on the maximum allowable spans for various purlin types, materials, and load conditions. They serve as a quick reference guide, eliminating the need for complex calculations and ensuring safe and efficient roof design.

Purlin span tables typically include the following information⁚

- Purlin Material⁚ The type of material used for the purlins, such as steel (C or Z shape), wood, or aluminum.

- Purlin Section⁚ The specific dimensions and cross-sectional shape of the purlin.

- Span Length⁚ The maximum permissible distance between supports for the purlin.

- Load Capacity⁚ The maximum load that the purlin can safely support, considering factors like snow load, wind load, and dead load.

- Bridging Requirements⁚ The recommended number of bridging rows for the specified span and load conditions.

- Slope⁚ The roof slope angle, which influences the load distribution and purlin requirements.

Purlin span tables can be found in various sources, including⁚

- Building Codes⁚ Local building codes often provide tables with minimum span requirements for different purlin types and load conditions.

- Manufacturer Websites⁚ Steel purlin manufacturers often provide detailed span tables for their specific products.

- Engineering Handbooks⁚ Engineering handbooks and reference materials typically contain comprehensive span tables for various structural elements.

- Online Calculators⁚ Several online calculators allow users to input purlin properties and load conditions to determine the maximum allowable span.

When using purlin span tables, it’s essential to ensure that the table is relevant to the specific project’s requirements and that the chosen purlin meets or exceeds the indicated span and load capacities.

Purlin Span Calculation

Calculating purlin span involves a meticulous process that considers various factors to ensure structural integrity and safety. The aim is to determine the maximum allowable distance between purlin supports while meeting load requirements and adhering to building codes.

The calculation process typically involves the following steps⁚

- Load Determination⁚ Calculate the total load that the purlin will be subjected to. This includes dead load (weight of the purlin, roofing material, and other fixtures), live load (snow load, wind load, and potential occupancy loads), and any additional loads specific to the building.

- Purlin Selection⁚ Choose the appropriate purlin type and section based on the calculated load and the desired span. Consider material properties like yield strength, modulus of elasticity, and section modulus.

- Span Calculation⁚ Employ engineering formulas and principles to determine the maximum allowable span for the chosen purlin based on the calculated load and material properties. This may involve using bending moment equations, shear force calculations, and deflection limitations.

- Code Compliance⁚ Ensure that the calculated span complies with local building codes and standards. These codes typically specify minimum span requirements and other design criteria for purlins.

- Bridging Considerations⁚ If the calculated span exceeds the recommended maximum for the chosen purlin, consider adding bridging to increase support and reduce deflection. Bridging is typically required for spans exceeding certain limits, depending on the purlin type and load conditions.

While purlin span calculations can be complex, using engineering software and online calculators can simplify the process. These tools often incorporate predefined formulas and material properties, making it easier to determine the maximum allowable span for specific purlin types and load conditions. However, it is crucial to consult with a qualified structural engineer for complex projects or when dealing with high-load applications.

Purlin Span for Different Materials

The choice of material for purlins significantly influences their span capabilities. Each material possesses unique properties that impact its strength, stiffness, and weight-bearing capacity. Understanding these characteristics is crucial for determining the appropriate purlin span for various applications.

Steel purlins, known for their high strength-to-weight ratio, are commonly used in commercial and industrial buildings. They offer long spans due to their robust nature and resistance to bending and buckling. However, their weight necessitates heavier support structures. Wood purlins, while less strong than steel, are readily available and often preferred for residential projects. Their flexibility allows for some movement, but their span capabilities are generally lower than steel.

Aluminum purlins offer a lightweight alternative with excellent corrosion resistance. However, their lower strength compared to steel limits their span potential. Composite purlins, combining wood and steel, balance strength and weight, providing a versatile option for various building types. They offer longer spans than traditional wood purlins while remaining lighter than steel. Ultimately, the choice of material depends on the specific project requirements, budget constraints, and desired aesthetic appeal.

To ensure the optimal purlin span for each material, it is crucial to consult with a qualified structural engineer; They can provide detailed calculations based on the specific building design, load conditions, and material properties. These calculations will guarantee the structural integrity and safety of the roof system while maximizing the efficiency and cost-effectiveness of the chosen materials.

Purlin Span and Building Codes

Building codes play a critical role in determining the permissible purlin span for a particular structure. These codes are established to ensure the safety and structural integrity of buildings, taking into account factors such as load capacity, wind resistance, and seismic activity. Adherence to building codes is mandatory for any construction project, and failure to comply can result in legal penalties and safety hazards.

Building codes specify minimum requirements for purlin spacing, material specifications, and structural support systems. These requirements vary depending on the geographic location, building type, and intended use. For instance, buildings located in areas prone to high winds or seismic activity will have stricter code requirements compared to regions with milder climates. It is essential to consult with local building officials to obtain the most up-to-date code information for your specific project.

The building code requirements for purlin spans are often presented in tables or charts, providing guidance on the maximum allowable span for different purlin sizes and material types. These tables take into account the expected loads, including dead loads (weight of the roof itself) and live loads (snow, wind, and other external forces). By following the code-specified span limitations, you can ensure that the roof structure can withstand the anticipated loads and maintain its stability throughout its lifespan.